Valve Spring Inspection

- Share

- Issue Time

- Jun 19,2019

Valve Spring Inspection

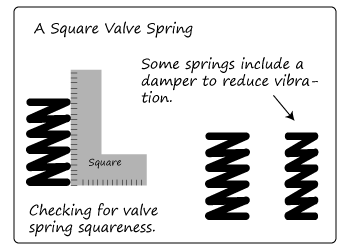

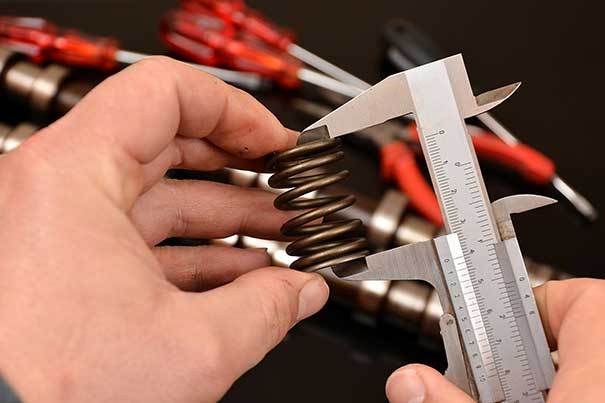

Valve springs should be inspected before installing them on the cylinder head. In fact, all valve train components and their geometry should be checked before reassembling the valve train. Valve springs are made from different metals depending on the engine. There are several designs other than standard springs. Some include a damper to reduce valve train vibration. Others are variable springs that change the distance in the space between the coils. Dual springs have a smaller spring located inside the larger one. This spring set dampens and reduces vibrations.

A weak or worn valve spring will result in valve float. Valves open and close at incredible speeds; a valve spring must be able to endure these extreme conditions. Valve float can result in damage to other components in the valve train.

Use a square and a flat surface to check valve spring squareness. Rotate the valve and make sure all the coils contact the square as it is rotated. A feeler gauge is sometimes used to measure tolerance. Check the manufacturer’s manual for any specifications or special procedures. Notice the space between the top coil and the square.