New product D-2028D pneumatic injector puller from DNT tools.

- Share

- Issue Time

- Apr 16,2024

Summary

Application:

• Tool for disassembling particularly fixed injection nozzles and glow plugs

• Compact and effective - the solution to problems in which a sliding hammer cannot be used

Characteristics:

Working torque: 20-30Nm

Working pressure: 5-8 bar (max)

Weight: 7Kg

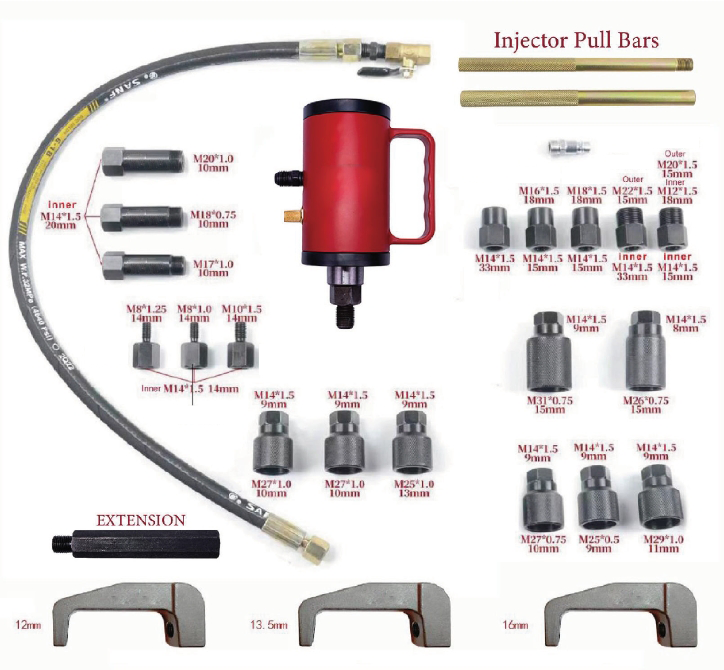

Composition:

(1x) air hydraulic hammer

(19x) adapter for various applications

Pneumatic Puller Set for Injector

Advantages of the Pneumatic Injector Puller include:

Fast and efficient operation: The tool uses pneumatic power to remove injectors quickly and efficiently, eliminating the risk of drag or damage

Safe Injector Removal: Accurate design and proper use of force allow injectors to be removed from the engine safely and without damage

Ease of use: The device has an ergonomic design, is easy to use and can be easily connected to the pneumatic system

Universal applicability: The Pneumatic Injector Puller is compatible with different types of injectors, so it can be widely used in different vehicles

Durable and reliable construction: The device is made of durable materials, so it has a long service life and works reliably during long-term use

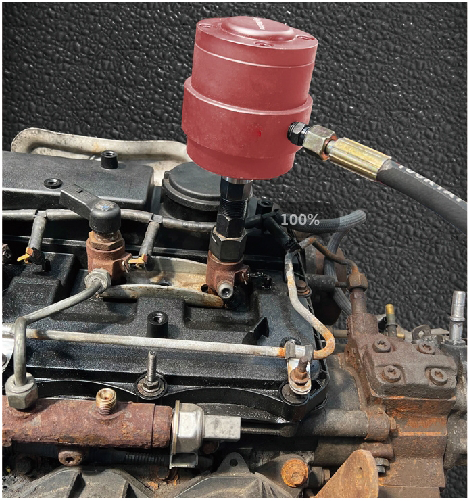

Step 1

Select the correct connector according to the injector. Place the Vibration Mate™ between the connector and injector, and tighten it.

The torque of the wrench is between 20-30Nm.WARNING: If loose it may cause damage during the impact drawing process. Please make sure it is torqued correctly.

Step 2

Use high pressure bar [the air pressure is generally between 5-8 bar]WARNING: If the air is not clean and free of moisture it will cause the internal cylinder of the Vibration Mate™ to be stuck or corroded. Use the air pressure switch to control the pulling frequency. Keep an eye on whether the injector is pulled out.

Step 3 When the injector is about to be pulled out, switch off or reduce the air pressure in order to prevent the injector head from hitting the engine's water bonnet or other parts.

Step 4 When the process is complete, store the Vibration Mate™ in its box in a dry place. Regularly inject about 1ml of oil into the air inlet of the puller every 10 hours of work to prevent the internal piston cylinder from becoming wet and causing rust.

|

Item No

|

D2028-D

|

|

Type

|

Pneumatic Injector Puller

|

|

Name

|

Pneumatic Puller Set for Injector

|

|

Suitable

|

Remove Injector

|