How to Install ZEX SOHC Cam?DNT Tools edited

- Share

- Issue Time

- Jul 13,2016

The ZEX SOHC Cam has been a popular choice amongst enthusiasts who prefer to stay in a Single Overhead Cam engine (SOHC), rather than opting out for the more popular B series Dual OverHead Cam engines (DOHC). And for those fearless enthusiasts, we’d like to take a look at the SOHC D series motor today, and how to install a ZEX cam and ZEX Springs without taking your motor apart!

This is a technical write up to inform you of how a camshaft and valve spring install is done with the cylinder head on the car. The install was done on a SOHC VTEC D16Y8 head. For the most part, this can be helpful with all Hondas, but of course there are differences between a VTEC and a non-VTEC head, and a SOHC or DOHC head. With that said, if you have anything other than a D16Y8 head I would recommend consulting another manual for at least the torque specs.

PARTS AND TOOLS:

The parts used in this install are the ZEX SOHC Cam #105300 and ZEX #912-16 valve springs. The specs on them are as follows:

ZEX D16Y8 #105300 Camshaft

VTEC Intake/Exhaust

Advertised Duration 260/268

Duration @ .050 220/216

Max Valve Lift .455/.430

Centerline 107/111

Lash .007/.009

ZEX D16Z6/D16Y8 #912-16 Valve Springs

.896″ Outside Diameter

.600″ Inside Diameter

Installed 50 lbs @ 1.950″, Open 170 lbs @ 1.050″

Spring Rate 240 lbs/in

Coil Bind Height 1.360″

Single Spring coil for both intake and exhaust

Here is a comparison of the stock spring next to the ZEX spring.

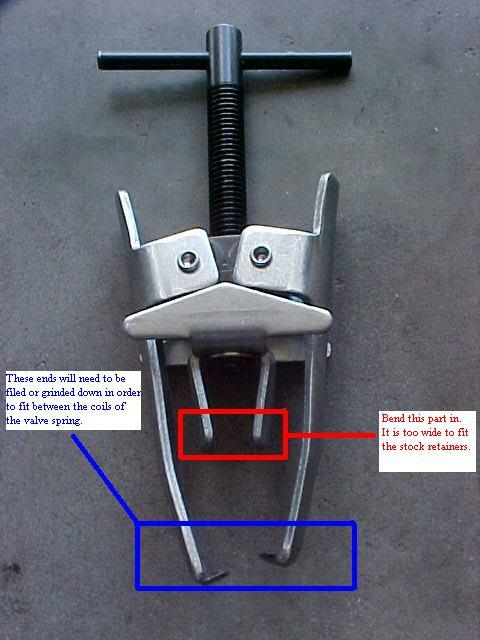

You will need a valve spring compressor to perform this job. This tool can be rented or purchased from many places like Sears or Autozone. A few modifications needed to be made to the valve spring compressor in order for it to be used with the 4 valve per cylinder Honda head.

You will also need a compressed air source and an adapter for the spark plug tube. Many cylinder compression gauges utilize a screw-in fitting that may work with your air hose quick-disconnect fitting. I removed the one-way valve from my Actron compression tester and used it.

These are the other tools you’ll need.

1.) Metric socket set

2.) Ratchet and extensions

3.) Timing light

4.) Torque wrench

5.) Feeler gauge

6.) Flathead screw driver

7.) Break-in lube (generally supplied by camshaft manufacturer)

INSTALLATION:

1.) Remove the valve cover.

2.) Set the engine at TDC for cylinder #1 and remove the cam gear.

3.) Remove the spark plug wires. Then unplug the distributor and remove the 3 bolts holding it to the head.

4.) Loosen the rocker arm assembly bolts a 1/4 turn each in the correct order until the spring pressure is relieved, but do not completely remove the bolts from the rocker arm assembly or it will start to fall apart on you.

5.) Lift the rocker arm assembly from the head.

6.) Lift out the stock camshaft. It’s going to drip oil everywhere, so you might want to have a couple shop towels ready.

7.) At this point you’ll want to take a look at the contact faces and adjuster tips of the rocker arms and make sure there is no excessive wear. Then take a look at the camshaft bearing surfaces on both the head and the rocker arms. Make sure there are no deep scratches or wear.

8.) Remove the spark plug in the cylinder you are about to install valve springs on, then thread the adapter into the spark plug hole and connect an air hose from a compressed air source.

9.) The valves should be held in place by the air pressure now. Stuff bits of paper towel in all your oiling holes and anywhere the keepers could fall into. Make sure it’s a big enough wad where it won’t soak up too much oil and fall into your engine.

10.) Use the valve spring compressor to compress the spring and remove the keepers with a magnetic screwdriver. I had a better picture of this, but don’t know what the hell happened to it.

Remove the keepers carefully as to not drop or misplace anything that would fall into your head or motor.

11.) Lift the valve spring and retainer from the head with the spring compressor.

12.) Compress the new valve spring with retainer using the spring compressor. (The retainer is not pictured here, I was only testing the spring compressor fitment at the time the picture was taken.)

13.) Place the end of the spring with the most closely wound coils towards the cylinder head and carefully place the keepers in between the valve stem and spring retainer.

14.) Relieve the pressure from the valve spring compressor and make sure the keepers are seated properly.

15.) Repeat steps 10-14 for the rest of the valve springs in the cylinder you are working on, then repeat the process for the other 3 cylinders.

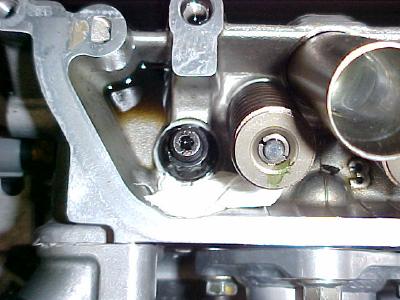

Here are the ZEX valve springs installed.

16.) Clean the camshaft, the bearing surfaces in the head and the rocker arms. Remove any dirt with a clean, lint-free cloth.

17.) Lubricate the camshaft bearing surfaces in the head and rocker arms and the lobes on the camshaft thoroughly with the provided assembly lubricant. Install the new camshaft seal with the open side facing in. Now carefully lower the camshaft into the head.

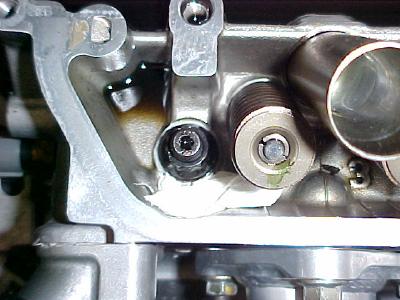

Put a drop of camshaft assembly lubricant on the bearing surfaces here, make sure your fingers are clean, and rub it in some.

Make sure the ZEX SOHC Cam is thoroughly lubed and set it in just like this.

18.) Apply sealant to the cylinder head contact surfaces next to bearings 1 and 5 and install the rocker arm assembly. Make sure everything lines up properly.

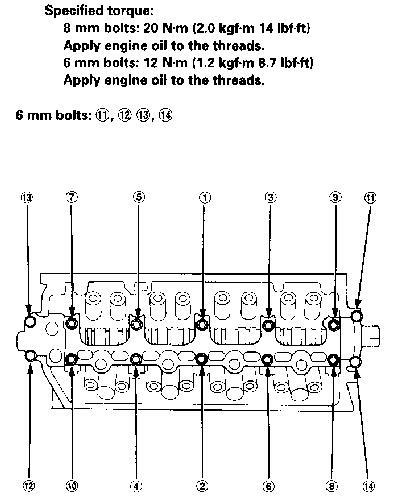

19.) Hand tighten the rocker arm assembly bolts a little at a time, in the proper sequence. Then torque them to Honda’s torque specifications in two or three steps, in the proper sequence.

D16Y8 Rocker Arm Assembly Torque Sequence and Specifications

20.) Place the cam gear and keyway on the end of the camshaft and torque it down. Make sure the cam gear is lined up at TDC with a straight edge. You will also want to check to make sure the bottom end is still lined up TDC as the air pressure may have moved it some. Now slip the timing belt back on and make sure it is tensioned properly.

21.) Put a new seal on the distributor and reinstall it. Make sure you have not turned it around 180 degrees.

22.) Now adjust the valve clearance to specifications.

23.) Rotate the crankshaft counterclockwise by hand for two complete revolutions. Recheck the alignment marks on the cam gear and crankshaft. The timing marks should still be aligned. If they’re not, remove the timing belt and set all the timing marks again.

24.) Torque the valve cover down and make sure all hoses, grounds, covers, and spark plugs/wires are installed at this point and you’re ready to start her up! Have the timing light handy and be ready to set your timing when the engine reaches operating temperature.