WHEEL BEARING REMOVAL / INSTALLATION KIT instruction

- Share

- Issue Time

- Jun 8,2022

WHEEL BEARING REMOVAL / INSTALLATION KIT

1. SAFETY

● Refer to instruction manual

● Wear eye protection

WARNING! Ensure all Health and Safety, local authority, and general workshop practice regulations are strictly adhered to when using

tools.

■ DO NOT use tools if damaged or worn.

■ Maintain the tools in good and clean condition for best and safest performance.

■ Ensure all threads are clean and well lubricated.

■ Ensure vehicle is adequately supported with axle stands, ramps, etc. as appropriate.

■ Wear suitable clothing to avoid snagging. DO NOT wear jewellery. Tie back long hair.

■ Wear approved eye protection. A full range of personal safety equipment is available from your Sealey dealer.

■ Account for all tools and parts being used and DO NOT leave them in or on the vehicle.

IMPORTANT: Always refer to the vehicle manufacturer’s service instructions, or proprietary manual, to establish the correct procedure and

data for the specific vehicle you are working on. These instructions for use are provided as a guide only.

2. INTRODUCTION

Comprehensive kit of tools for the fast and effective removal and Installation of wheel bearings on front-wheel drive vehicles. Reduces chances of

damage to hub and bearing. Heavy-duty steel drifts with phosphate coating to prevent corrosion. Heavyweight drive screw for use with impact tools.

Also suitable for removing and installing large industrial bearings. Supplied in carry-case

3. SPECIFICATIONS

|

Model No:

|

DN-D1023

|

|

Drift Sizes Ø:

|

55, 60, 64, 67, 73, 75, 78, 82, 84, 88mm

|

|

End Cap Ø:

|

50mm

|

|

Sleeve Ø External:

|

76, 86, 92, 101mm

|

Hub screw length: | 210mm |

Hub screw drive: | 32, 38mm |

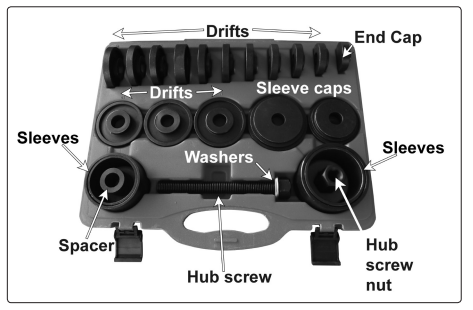

4. CONTENTS

5. OPERATION

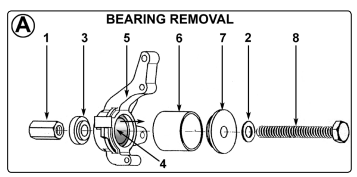

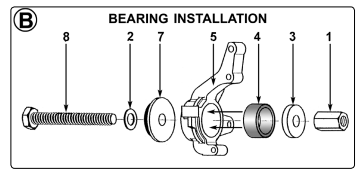

1. HUB SCREW NUT 2. WASHER 3. DRIFT 4. BEARING 5. VEHICLE HUB 6. SLEEVE 7. SLEEVE CAP 8. HUB SCREW

BEARING REMOVAL:

Identify the correct sleeve (6) to sit on the outside of the bearing housing and the correct drift (3) to drive the bearing from the housing. Assemble as shown in A using the correct sleeve cap (7). Keep the hub screw and nut well lubricated whilst driving out the bearing.

BEARING INSTALLATION:

Identify the correct sleeve cap (7) to sit on the outside of the bearing housing and the correct diameter drift (3) to drive the new bearing into the housing. Assemble as shown in B. Keep the hub screw and nut well lubricated whilst driving the new bearing into the housing. The 50mm end cap is used to locate into the back of the drifts; they can then be used in a workshop press when it is not possible to use the hub screw.