Why should I replace my shocks?

- Share

- Issue Time

- Aug 17,2022

Replacing the shocks or struts in your car is often a game changed. These suspension components wear out slowly as your put miles on your car so as the owner we’re often not even aware of how bad things have gotten. Shock manufacturers recommend replacing your shocks or struts every 60,000 miles. since you’ve probably got more miles than that in your shocks you might wonder why you should replace them so often.

Why should I replace my shocks?

Replace your shocks before they are completely blown has a little to do with ride quality but a lot to do with safety. Poorly functioning shocks and struts can significantly increase your stopping distance as well as the chance of a rollover. Hopefully, you’ll never have to test this in your car but when you get in a sticky situation you want your vehicle to react how to expect and to perform it’s best to keep you and others safe.

how to use a spring compressor?

On many vehicles, you may be able to get around it by purchasing loaded struts. If loaded struts aren't available for your vehicle, you’re going to need to use a spring compressor.

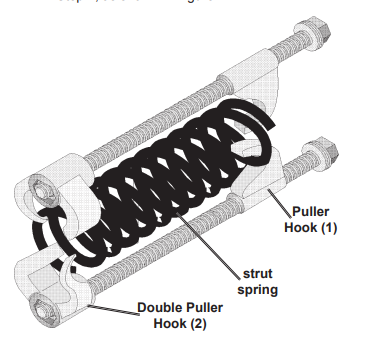

There are 2 types of spring compressors that accomplish the same task but you have to use the right one for your setup. One type of spring compressor goes up through the center of the spring and grabs the coils from inside. This type of compressor is usually used simply to remove the spring on trucks and older cars but you usually don’t need it to change the shocks on that type of vehicle.

The other type of spring compressor is 2 identical pieces that go on either side of the spring This type of spring compressor is used when the shock goes up inside the spring either on a strut like this or on a coilover type setup.

it’s very important to compress the spring enough so that it’s loose on the shock before you try to take anything apart. This is important because there is a ton of stored energy in that sprint when it’s mounted to the shock. It can take anywhere from 100 to 500 lbs of force per inch to compress one of these springs. If the spring is allowed to decompress suddenly, like if you remove the shock top nut, it can do a lot of damage and cause significant injury.

The biggest tip we can give you is to make sure the fingers of the spring compressor are securely over the coil and you compress the spring evenly. Your spring should stay looking like a straight cylinder not be curved or bent from being compressed on one side more than another.

While talking this job yourself can seem scary it can really save you lots of money.