How ZF Gearbox Repair Works: Step-by-Step Guide

- Share

- Issue Time

- Jul 3,2025

How ZF Gearbox Repair Works: Step-by-Step Guide

ZF gearboxes are widely used in commercial trucks, heavy-duty vehicles, marine equipment, and construction machinery due to their reliability and advanced mechatronic systems. However, like all mechanical systems, they require periodic repair or overhaul to ensure continued performance and safety.

In this blog, we’ll walk you through a detailed ZF gearbox repair process, from inspection to final testing — while also introducing how NBDN Tools, a leading manufacturer of truck repair tools, empowers workshops and professionals with the right tools and technical knowledge for successful gearbox repairs.

1. Initial Diagnosis and Problem Detection

- Use OBD scanners to extract transmission fault codes.

- Inspect transmission fluid — check for contamination, burnt smell, or metal shavings.

- Road test the vehicle to identify shift delays, slipping, or abnormal sounds.

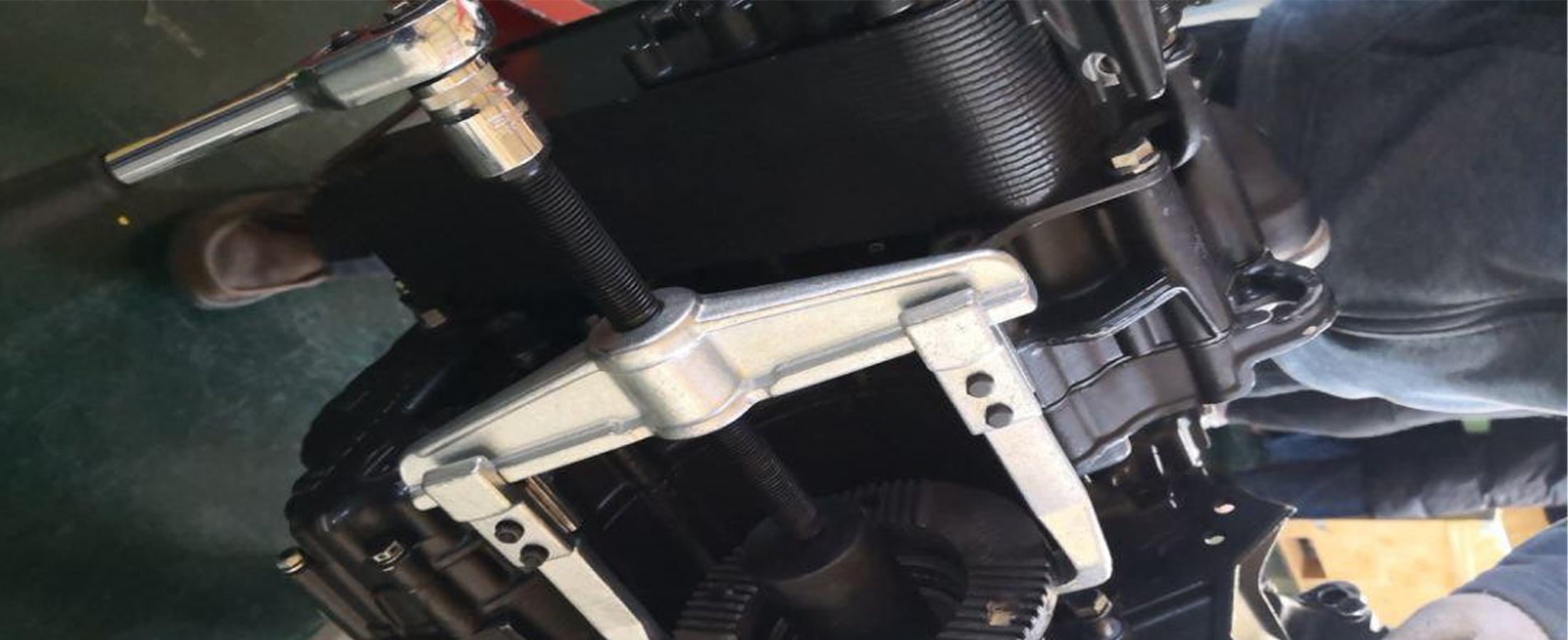

2. Disassembly and Inspection

- Drain the transmission and clean all external surfaces.

- Use NBDN’s gearbox disassembly tool sets for safe removal of the transmission unit.

- Systematically disassemble: remove oil pan, valve body, solenoids, torque converter, and clutch assemblies.

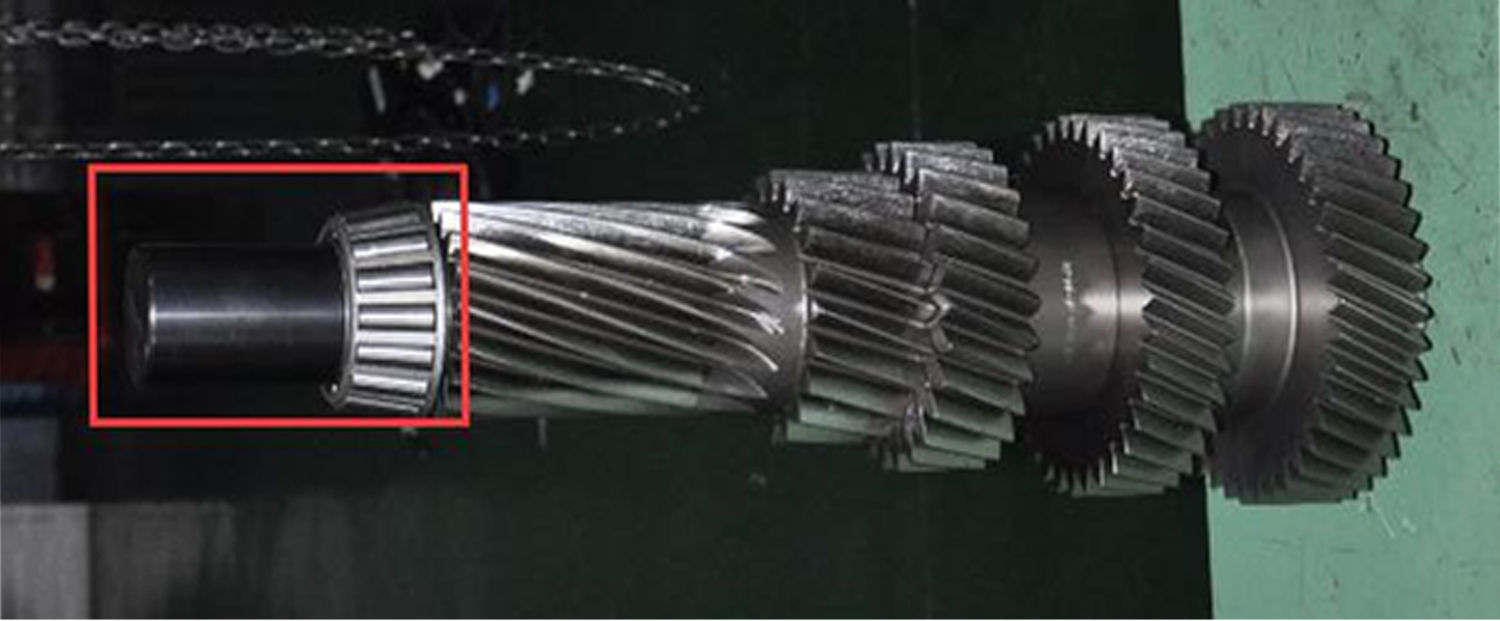

- Inspect gears, bearings, pump, and clutch plates for wear or scoring.

3. Component Testing & Cleaning

- Test solenoids for correct resistance values and response.

- Hydraulically test the torque converter and oil pump using test benches.

- Clean all reusable components with non-abrasive methods (ultrasonic preferred).

4. Replacement & Reassembly

- Replace worn clutch packs, gaskets, seals, and faulty electronic units with OEM-grade parts.

- Use torque specifications and alignment tools to reassemble internal components.

- Reinstall valve body, filter, and transmission pan using precision torque tools from NBDN.

5. Final Testing and Calibration

- Refill fluid with ZF-recommended ATF.

- Perform static and dynamic pressure testing.

- Use diagnostic software to reset adaptations and calibrate the mechatronic unit.

- Conduct road tests under various loads to validate shifting performance.

6. Why Choose NBDN Tools for ZF Gearbox Repair?

At NBDN Tools, we specialize in professional-grade repair tools for heavy-duty truck systems, including ZF, Allison, and Fast Gear transmissions. Our R&D team focuses on the needs of commercial repair shops, offering:

- Custom ZF transmission disassembly/rebuild toolkits

- Pressure testing adapters and solenoid test tools

- Clutch adjustment tools and torque converter locking systems

- Fast delivery, OEM compatibility, and engineering support

With our tools, technicians can perform accurate and efficient gearbox repairs, reduce labor time, and ensure long-term system reliability.

7. Conclusion

ZF gearbox repair is a complex but manageable task when supported by the right tools and expertise. Whether you run a repair shop or manage a fleet, understanding the process and using reliable tools from NBDN Tools ensures quality outcomes and customer satisfaction.

For tool inquiries or to explore our full product catalog, get in touch with us today.