New instructions_Slide Hammer and Bearing Puller Set

- Share

- Issue Time

- Jul 26,2022

Summary

New instructions_Slide Hammer and Bearing Puller Set,wholesaler and manufacturer of inner bearing puller,Custom,OEM

New instructions_Slide Hammer and Bearing Puller Set

|

Specification

|

||

|

Collet Size /

Bearing Depth

|

3/8" – 1/2"

(1-1/2" Maximum Bearing Depth / 3/8" Hex Drive) 9/16" – 11/16 " (1-3/4" Maximum Bearing Depth / 3/4" Hex Drive) 5/8" – 1" (1-3/4" Maximum Bearing Depth / 3/4" Hex Drive) 1" – 1-1/4" (2" Maximum Bearing Depth / 1" Hex Drive) |

|

|

Slide Hammer

Weight

|

3 lb with Handle 1.95 lb without Handle

|

|

Operating Instructions

NOTE: To open or close the Attachment

Clamps, grasp the Attachment head

firmly and twist the Handle (2) of

the Slide Hammer. A clockwise

motion will open the clamps, while

counterclockwise motion will close them

1. After threading the proper Attachment (3, 4, 5 or 6) onto the end of the Slide Hammer (1) make sure the clamps of the Attachment are completely closed.

2. Insert the Attachment head into the

inner diameter of the bearing.

3. Grasp the Attachment head while

turning the Handle clockwise until

the Attachment clamps open and are

snug against the bearing lining.

4. Firmly grasp the Slide Hammer and

Handle with both hands. Spread

your feet shoulder-width apart.

5. Gently push Slide Hammer forward.

Make sure your fingers are not in

the way of the sliding action.

6. Forcefully pull Slide Hammer backward

towards your body. Watch bearing

for movement. Bearing should pull

out evenly. If the Bearing pulls out

unevenly during this operation, stop.

Remove the Bearing Puller and gently

tap the bearing with a rubber mallet

until it is even, then start again.

7. Repeat steps 4 thru 6 until bearing has

successfully pulled free of its location.

8. Close the Attachment clamps by

twisting Handle counterclockwise.

Then remove the bearing

Maintenance and Servicing

1. BEFORE EACH USE, inspect the general condition of the Bearing Puller. Check for loose attachments, misalignment or binding of moving

parts, cracked or broken attachments, and any other condition that may affect its safe operation. If any abnormality is found, have the problem

corrected before further use.

2. AFTER EACH USE, wipe off Bearing Puller with clean, moist cloth.

3. Lubricate Attachments regularly to ensure smooth operation.

4. Replace Attachment if threads begin to wear and it will not attach to Slide Hammer.

|

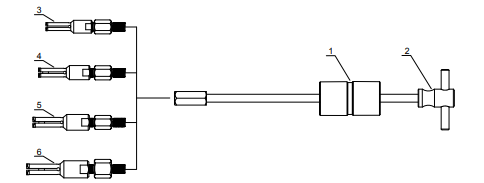

Parts List and Diagram

|

||

|

Part

|

Description

|

Qty

|

|

1

|

Slide Hammer

|

1

|

|

2

|

Handle

|

1

|

|

3

|

Attachment 3/8" to 1/2"

|

1

|

4 | Attachment 9/16" to 11/16" | 1 |

5 | Attachment 5/8" to 1" | 1 |

6 | Attachment 1" to 1-1/4" | 1 |