Heavy Duty Shock Spring Compressor Tools For cars|left hand type spring compressor|Safety to repair car shock absorber

- Model

- DN-B2002/B2001/B2003

Item specifics

- type

- spring compressor

- Material

- SAE1045

- Technic

- Drop Forge

- Hardness

- 38-42 HRC

- application

- compress coil spring

- package

- Carry case

- Suitable

- New model cars

- application

- replace and repair car shock more safety

- sample

- accepted sample order

- Service

- OEM,ODM,Customized

- Carry Case Color

- Red,blue,black

Review

Description

DNT Tools is a Chinese Reliable Manufacturing vendor, Wholesale tools offer OEM,ODM Custom New Tools Service focus on high-end market

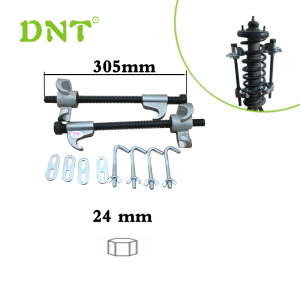

Heavy Duty Shock Spring Compressor Tools For cars-left hand

Suitable for MacPherson strut coil springs.

Features a yoke extension bracket that also allows use on conical springs. Supplied with three pairs of diƬ erent sized interchangeable yokes, for a wide range of vehicle applications.

Plastic yoke protectors that protect the spring coating from damage, which can invalidate the vehicle manufacturer's guarantee.

Safety yokes are carefully shaped to stop the spring bowing while under compression.

|

Item No

|

Compressor

|

Gold Yokes

Φ80-105mm |

Handed

|

Black Yokes Φ105-150mm | Handed | Silver Yokes Φ145-190mm | Handed |

|

B2001

|

YES

|

YES

|

N/A

|

YES | L/H | YES | L/H |

B2002 | YES | YES | R/H | YES | R/H+L/H | YES | R/H+L/H |

|

B2003

|

NO

|

NO

|

N/A

|

YES | L/H | YES | L/H |

|

YES

|

YES

|

R/H

|

YES | R/H | YES | R/H |

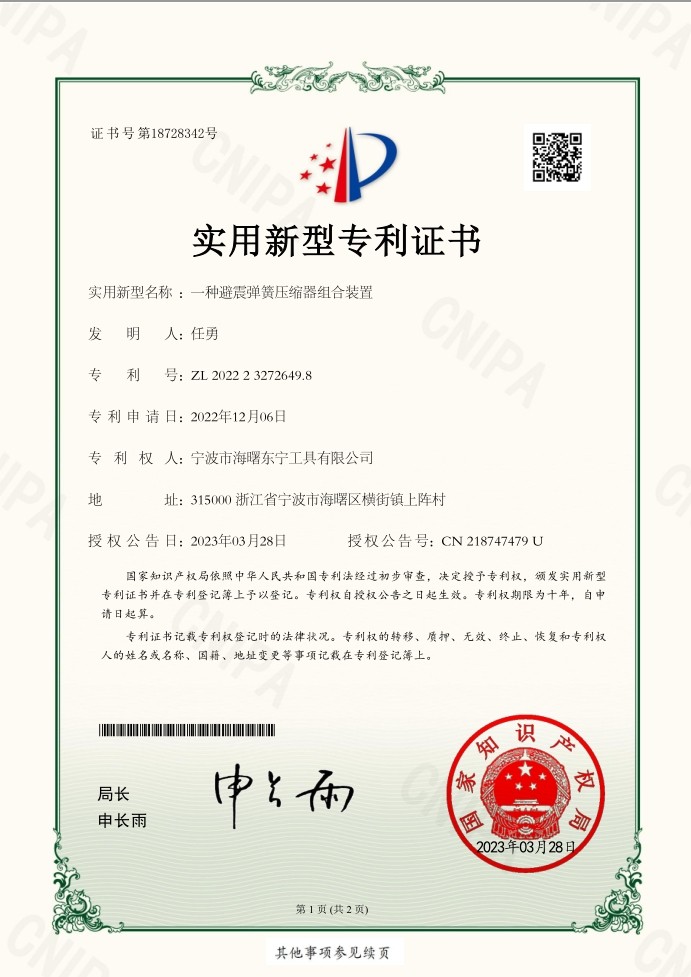

Patent No. ZL 2022 2 3272649.8

Package Custom

Operation

Tips:

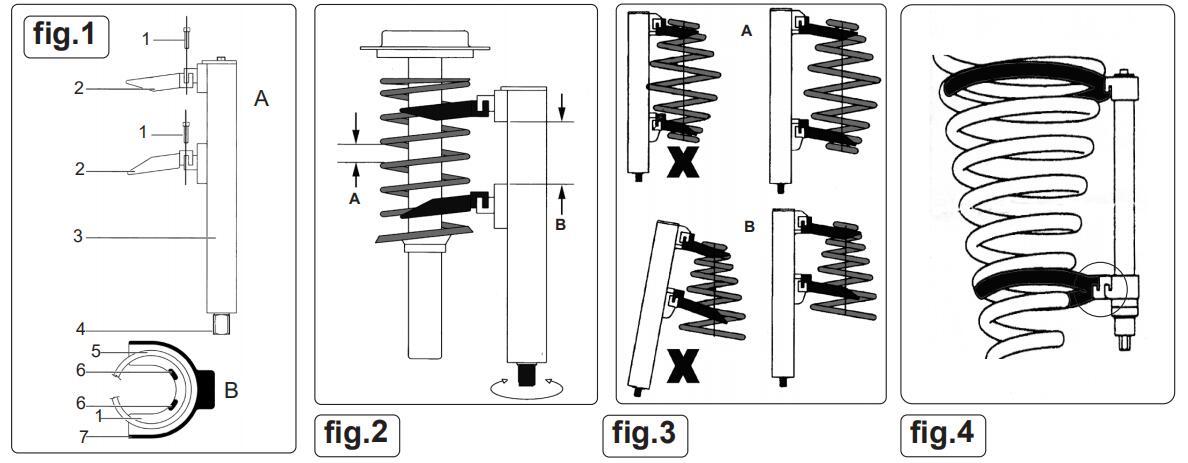

WARNING! DO NOT compress the spring to an extent where the coil windings touch, fig.2.A.

WARNING! DO NOT compress the spring to an extent where the jaws touch fig.2.B.

Ensure the jaws and the body of the compressor are correctly aligned at all times during spring compression fig.3.A. For conical springs, the centre line of the spring should remain parallel to the compressor body, fig.3.B.

If necessary use the extension block as in fig.4 to keep the spring and compressor body parallel.

Secure the strut with a clamp, vice, or other adequate holding devices.

TO COMPRESS A STRUT REMOVED FROM A VEHICLE

Mount the selected jaws on the compressor body, fit the retaining bolts and tighten securely.

Rotate the hexagonal nut, using air or hand tools to drive the jaws apart to the length of the spring and to allow compression of as many windings as possible.

Place the spring strut compressor onto the spring, ensuring the spring seats correctly, fig.1.B., between the safety lips, fig.1.6. and the outer rib fig.1.7. and cannot slide out during compression.

Ensure the jaws and body are correctly aligned, fig.3 / 4.

Rotate the hexagonal nut, using air or hand tools and compress the spring until the upper support bearing is free and the spring will rotate

TO DECOMPRESS A STRUT REMOVED FROM A VEHICLE

To decompress the spring, reverse the compress procedure.

Buy Guide:

Service

1. Offer OEM Service for brand tools,there are more than 20 years experiences

2. Accepted Customized Service for new tools to explore markets

3. Accepted original design & customized color carton,label,according to UI

4. Only product HQ Tools

5. Accepted OEM and ODM service(according to customer demand production of products that meet the customer requirements and design processing (ODM) in accordance with customer requirements, design, OEM production meets the requirements for the customer the product, the development of manufacturing technology and ability)

FAQ

Q0: Where is your market?

A: We have customers world widely. And our main market is in Europe, US.

Q1:How to get free sample?

A:Yes . Sample are welcome for us . But products cost and shipping fee will be charged from customer , the sample cost will be returned back in formal order

Q2:Do you have MOQ for order?

A: Yes, our MOQ should be 100-500 pcs t based on different items.

Q3: Can you do OEM for us ?

A:Yes, our MOQ should be 100-500 pcs t based on different items,Customers' brand ,logo , label can be customized for the products and carton package , but based on a certain quantity .

Q4: Could you custom new tool? how to do it?

A:Yes,We own a technical tearm,they will help customer to custom NEW Tools according to sample,drawing,or customer's good idea about new tools.Meanwhile we will sign confidentiality agreement with custom to protect customer's right

Q5: what are your main products?

A:DNT Tools is source tool manufacturer from China,Main product are hand tools,tool sets,workshop tools and mechanic tools.contain:bearing puller,nut splitter,Hydraulic pullers,hydraulic nut breakers,and so on.

Q6: What is your terms of packing?

A:Generally, we pack our goods in neutral white boxes,brown cartons and Carry case. lf you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters. We can also Design the packing fit your local market.

Q7: How about your delivery time?

A: Generally, Delivery time for new customer will be around 45 days.

But for old customers, packing designs have been confirmed.

We will be able to finish production earlier.

Q8: Do you test all your goods before delivery?

A: Yes, we have test before delivery.and make QC Report to customer

Q9: How do you make our business long-term and good relationship?

A:1. We keep good quality to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.